6.13.1 Engine systems

6.13.1.1 Fuel oil systems

Large marine diesel engines consume a large amount of fuel oil. Therefore, it is not economical to run them continuously on diesel oil. Marine engines are normally operated on Heavy Fuel Oil (HFO), which is cheaper than diesel. Diesel oil is also available onboard to use in special situations.

Heavy fuel contains a lot of impurities such as sludge and water. Therefore, it has to be treated before use. On top of that, heavy fuel viscosity is also very high, so viscosity has to be reduced in order to treat, pump, and consume it effectively.

Fuel to be used is first transferred from storage tanks to a settling tank in which it is heated to allow some water and sludge to settle out by gravity and be drained off. The fuel is then passed through a centrifugal separation system and discharged to a daily tank (service tank).

Fuel oil system with flow indication.

From the daily service tank, the oil flows through a three-way valve to supply pumps via a filter. These supply pumps supply fuel into mixing tanks (buffer tank) via a filter which removes impurities in the fuel oil. The mixing tank assists in the gradual mixing of HFO and Diesel oil during changeover, helps to purge air from the system, and also provides a constant pressure head to the system.

A flow meter is fitted before the mixing column to indicate fuel consumption. Booster pumps or circulating pumps are used to pump the oil through heaters and a viscosity regulator (viscotherm) to the engine fuel pumps. There is a fine filter immediately before the fuel pumps to remove fine impurities. The fuel pumps provide high-pressure fuel to their respective injectors.

The viscosity regulator or viscotherm varies the fuel oil temperature in order to provide the correct viscosity for combustion. Fuel oil is heated by steam in fuel oil heaters. A return line pressure control valve ensures a constant-pressure supply to the fuel pumps.

Excess fuel from the engine fuel pumps is returned back to the buffer tank, but provision is provided to divert return oil to the service tank. A diesel oil daily service tank may be installed and is connected to the system via a three-way valve. Relief valves are used to release excess pressure.

6.13.1.2 Lub oil systems

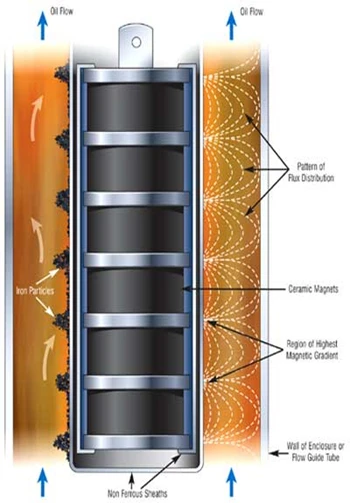

The lubrication system of an engine provides a supply of lubricating oil to the various moving and rotating parts in the engine. Its main function is to enable the formation of a film of oil between the moving parts, which reduces friction and wear. The lubricating oil is also used as a cleaner and as a coolant.

Lubricating oil for an engine is stored in a drain tank located beneath the engine. The oil is drawn from this tank through a strainer by a lube oil pump. The oil is then passed through a cooler and a Temperature control valve which regulates flow through the cooler to maintain the oil at the correct temperature (and therefore viscosity) at the inlet to the engine. Then the oil is sent through a fine filter before sending it to the engine in order to remove fine impurities. A Sample Cock enables drawing off a sample for analysis.

6.13.1.3 Piston cooling system

Marine diesel engines have a number of cooling systems to maintain optimum operating temperatures. One of these systems is the piston cooling that is achieved using either oil or water as a cooling medium. Originally, water was preferred; however, modern diesel engines mostly use oil.

6.13.1.3.1 Piston cooling oil system

The oil is drawn from the main engine sump by the lube-oil pump, being discharged to a manifold bolted to the outside engine casing. From here, an internal swinging arm piping system supplies oil to the crosshead bearing and the piston cooling.

The cooling oil is delivered to the piston crown, through the center of the hollow piston rod, circulating through the cooling channels in the piston. The oil returns through the piston rod via small holes, where it is collected in a tray at the crosshead bearing. Here the oil temperature is monitored before spilling over the tray, cascading down into the main lube-oil sump.

6.13.1.3.2 Piston cooling water system

A centrifugal pump supplies the cooling water under pressure to the piston, where it is circulated through water channels that have been cast into the piston.

The water enters and leaves the piston through telescopic pipes that slide up and down on standpipes as the piston reciprocates. The water temperature is maintained by a dedicated seawater cooler, and a header tank allows the system water and additive to be topped up and also provides a positive head to the system.

A cooling water storage tank is in the system; here the water flows into the tank from the return line, where it passes through a filter plate. The cooling water pumps then draw the water from here, circulating the water through the pistons and cooler.

6.13.1.4 Jacket Cooling Water

The cooling water pump (which may be engine driven or a separate electrically driven pump) pushes the water around the circuit. After passing through the engine, it removes the heat from the cylinder liners, cylinder heads, exhaust valves and sometimes the turbochargers. It is cooled by seawater and then returns to the engine. The temperature of the cooling water is closely controlled using a three-way control valve.

The cooling water outlet temperature is usually maintained at about 80-85C.

A Header tank is used to provide pressure head to the pump, and it makes up any system losses. Vents from the system are also led to this header tank to allow for any expansion in the system and to get rid of any air. The header tank is deliberately made to be manually replenished and is fitted with a low-level alarm. This is so that any major leak would be noticed immediately.

The system will also contain a heater which is to keep the cooling water hot when the engine is stopped, or to allow the temperature to be raised to a suitable level prior to starting. A freshwater generator (FWG), which is used to produce fresh water from sea water, is also incorporated into the jacket water system.

A drain tank has been included. This is to drain the engine cooling water for maintenance purposes. Because of the quantities of water involved and the chemical treatment, the water can be reused.

6.13.1.5 Cooling of fuel valve

When burning heavy fuel oil, Nozzle cooling is required as injectors are exposed to high temperature during combustion.

Some injectors have internal cooling passages in them extending into the nozzle through which cooling water is circulated. This is to prevent overheating and burning of the nozzle tip.

The water is circulated from a tank via a pump, cooler, and cooling spaces in the injector nozzle tips before being returned to the tank via individual return pipes. The tank is equipped with a heating coil to maintain the water temperature at 70C when the engine is stopped. An observation window is provided as a means of checking that the tank is clear of fuel oil contamination. If contamination occurs, the faulty injector can be identified by taking samples from the individual returns. Some cooling systems use oil as the coolant.

6.13.1.6 Starting air system

Diesel engines are started by supplying compressed air into the cylinders in the appropriate sequence for the desired rotating direction. A supply of compressed air is stored in air reservoirs or 'bottles' ready for immediate use. The starting air system usually has interlocks to prevent starting if everything is not in order (e.g., if the turning gear is engaged).

Compressed air is supplied by air compressors to the air receivers. Then it is supplied by a large bore pipe to a remote operating automatic valve and then to the cylinder air start valve. The automatic valve is only open whilst an air start is taking place. The air start valve is located in the cylinder head, and its purpose is to supply starting air into the cylinder.

The opening of the air start valve is controlled by a pilot air system. The pilot air is supplied in the correct sequence by the starting air distributor.

-

A Bursting disk is present to burst in case of excess pressure in the starting air manifold.

-

A Non-Return (N/R) valve is to prevent back flow of hot gases to the starting air bottles in case of a starting airline explosion.

6.13.1.7 Scavenge Combustion Air and Exhaust Passage

Scavenging is the process of removing exhaust gases from the cylinder after combustion and replenishing the cylinder with fresh air.

The exhaust gas is sent to the exhaust manifold via exhaust valves. This exhaust gas is used to drive the turbocharger (Turbo charger is explained under 6.11). The turbocharger gas outlet goes to the funnel via the economizer.

Fresh air drawn through the turbocharger filter is compressed and sent to the scavenge air manifold via a cooler. (When the air is compressed, its temperature increases, thus reducing its density. Therefore, cooling is necessary in order to increase the density of air.) Then scavenge air is sent to the under-piston space via non-return flaps or valves.

The scavenge air enters the cylinder through the scavenge ports in the lower part of the cylinder liner.

6.13.2 Sketches an air reservoir, identifying all of the fittings.

Air Bottle Mountings and Connections

The general mountings and connection present on the air bottle of a ship are:

-

Filling valve: This is a valve fitted in the supply connection from the main air compressor to the air bottle.

-

Outlet to Main engine: An outlet valve and pipe is fitted for connection from the air bottle to the main engine for supplying air during starting. This is a slow turning screw down valve.

-

Outlet to auxiliary engine: An outlet valve and pipe is fitted for connection from the air bottle to auxiliary engines for supplying air during starting.

-

Auxiliary connection: Other auxiliary supplies connections such as service air, safety air, etc., are also provided with an isolating valve.

-

Relief valve: A relief valve is fitted on the air bottle to relieve excess pressure inside the bottle. Normally this is let to the outer atmosphere.

-

Drain valve: A drain valve is fitted at the bottom of the bottle to drain accumulated condensate from the receiver.

-

Fusible plug: A fusible plug is fitted in the bottle with a separate connection leading out of the engine room so that in the event of fire, this plug will melt and relieve all air to the outside the engine room.

-

Manhole door: A manhole door is fitted in the bottle to carry out inspection of the same.