6.8 Fuel Treatment

6.8.1 Filters Used in Fuel Lines

Mechanical separation of solid contaminants from various systems (fuel, lubricating oil, etc.) is achieved by the use of filters and strainers.

6.8.1.1 Strainers

A strainer is a device used to separate unwanted solids from a liquid by filtering. A strainer should be cleaned as soon as it is taken out of the system, then reassembled and left ready for use.

6.8.1.2 Gauze Filter

The strainer usually employs a mesh screen, an assembly of closely packed metal plates, or wire coils which effectively block all particles. It is typically fitted on the suction side of a pump to prevent damage to the pump components due to unwanted solid particles. The particles of dirt collect on the outside of the strainer element or basket and can be removed by compressed air or brushing.

6.8.1.3 Edge – Type Packs

The edge-type pack is an improvement on the simple wire gauze mesh strainer and can be cleaned whilst in operation, filtering out very small particles.

-

The dirty oil passes between a series of thin metal discs mounted upon a square central spindle.

-

Between the discs are thin metal star-shaped spacing washers of slightly smaller overall diameter than the discs.

-

Cleaning blades, fitted to a square stationary spindle and the same thickness as the star-shaped washers, are located between each pair of discs.

-

As the oil passes between the discs, solid particles larger than the spacer between the discs remain upon the periphery of the disc stack.

-

The filter is cleaned by rotating the central spindle; this rotates the disc stack, and the stationary cleaning blades scrape off the filtered solids, which then settle to the bottom of the filter unit.

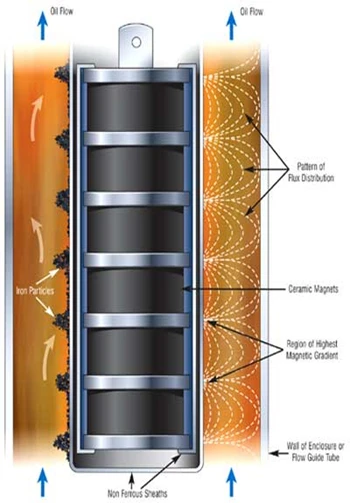

6.8.1.4 Magnetic Filters

A typical magnetic filter body is made of an aluminum alloy or bronze. The construction is similar to a mesh filter, but a permanent magnet is attached to the center core bolt. The resulting magnetic field magnetizes the wire mesh, attracting and trapping all magnetic particles within the mesh and on the magnet.

These filters can be difficult to clean as the fine metal particles stick very strongly to the mesh and magnet. They are commonly used in the lube oil system to catch fine ferrous particles.

6.8.1.5 Fiber Assemblies (Coalescent Filters)

Coalescent is the process by which two or more separate masses of miscible substances "pull" each other together to make a larger particle.

Coalescent filters remove solid particles as well as water. After passing through a conventional filter, the oil flows through a special fibre assembly. This filter operates on the principle that the molecular attraction between water droplets and the mesh is greater than the attraction between the oil and the mesh. The water droplets coalesce and fall to the bottom of the filter unit, while the oil passes through the mesh.

6.8.2 Gravity Separation Principles

All objects on Earth experience a gravitational force that is directed downward towards the center of the earth. The separation of particles based on their gravity is one of the oldest and most commonly used separation techniques.

Gravitational force = mass x gravitational acceleration

When discussing the separation of liquids and solids, density is considered instead of mass Density = mass / volume . Since densities of solids are greater than densities of liquids, the gravitational force exerted on a solid is greater than that on a liquid.

In a mixture of solids, oil, and water in a container:

-

Solids particles will move to the bottom due to the largest gravitational force.

-

Water (which is denser than oil but lighter than solids) will settle above the solids.

-

The lightest density oil will stay at the top.

Settling tanks are employed, where the oil is allowed to stand undisturbed. Mediums of higher relative density than the oil gravitate to the bottom and are discharged periodically through a drain valve. This process can be accelerated by heating the tank contents, typically using steam heating coils.

6.8.3 Centrifugal Separation vs. Gravity

The separation by sedimentation of two liquids, or of a liquid and a solid, depends on the effects of gravity on the components. This separation can be very slow if the specific gravities of the components are not very different, or if the gravitational force is simply not sufficient to speed up the process.

To accelerate the rate of separation, much greater forces can be obtained by introducing centrifugal action. The resulting centrifugal force accelerates the process significantly. It's not unusual for a centrifuge to impart 6,000 times the force of gravity on the liquid contained within while spinning at 7,000 to 9,000 rpm.

By rapidly spinning, the comparatively weak force of gravity that normally acts upon the substances is multiplied several thousand times. Therefore, centrifugal separation is much faster and more effective than gravity in the separation process.

6.8.4 Correct Procedure for Disposal of Waste Oil, Sludge, etc.

Sludge is to be considered as “contaminated, hazardous and toxic” and must therefore be handled with care by competent staff using appropriate equipment and protective clothing.

Residual waste, such as sludge containing oil or petroleum waste from the engine room, must be disposed of in a safe and responsible manner and in full compliance with international and local regulations.

-

No disposal of waste oil sludge can be done into the sea or any waterways.

-

Slop or sludge tanks on the vessel are to be used for the preliminary storage of such waste.

-

Disposal will be either directly to shore facilities or by the use of onboard incinerators or by other acceptable means.

-

Ship incinerators are a furnace designed for burning dry waste, wet waste, sludge oil, and most kinds of solid waste.