6.9 Types of Engines

6.9.1 Engine Categories by Bore and Rotational Speed

Marine diesel engines are normally described in broad categories by the bore of their cylinders and their rotational speed.

-

Bore – refers to the inner diameter of the engine cylinder.

Engines are categorized by the size of the cylinder bore as:

-

Large bore

-

Small bore

Marine diesel engines are also categorized by their rotational speed:

Slow Speed Engine

-

Speed: 70 – 200 rpm

-

Cylinder bore: 500 mm and above

-

Output / Power: 3,000 – 100,000 bhp

Medium Speed Engine

-

Speed: 400 – 1,200 rpm

-

Cylinder bore: 100 – 350 mm

-

Output / Power: 1,000 – 8,000 bhp

High Speed Engine

-

Speed: 1,200 rpm and above

-

Cylinder bore: 130 – 180 mm

-

Output / Power: 250 – 800 bhp

6.9.2 Large-Bore Engines: Piston Rods and Crossheads

Large-bore engines are normally fitted with piston rods and crossheads.

In this design, an additional component called the crosshead is used to achieve the swinging action of the connecting rod and to transfer the horizontal thrust to the cylinder liner. It also guides the piston to move centrally in the liner.

-

The piston is rigidly fixed to the piston rod.

-

The rod passes through a gland to a crosshead to which it is attached via a flange or shoulder through bolt and nut.

-

The crosshead assembly slides up and down in guides.

-

The crosshead assembly is connected to the crankshaft by the connecting rod with bearings.

-

Due to this design, it is possible to achieve a smaller turning radius of the crankshaft, even for large piston strokes.

6.9.3 Smaller Diesel Engines: Trunk Pistons and Gudgeon Pins

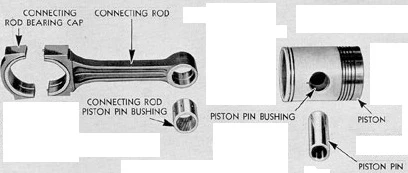

Small-bore engines are commonly equipped with only one connecting rod and use a trunk piston and a gudgeon pin in place of a piston rod and crosshead.

-

The piston is connected directly to the upper end of the connecting rod by the gudgeon pin (Piston pin) and bearings.

-

The lower end of the connecting rod is connected to the crankshaft with a bearing.

6.9.4 Large-Bore Engines and Low Propeller Speed

Large-bore engines are normally directly connected to the propeller and therefore rotate at low speed.

Propeller efficiency is highest when the propeller speed is low. As large-bore engines are directly connected, the engine RPM must also be lower to gain high efficiency.

6.9.5 Other Diesel Engines and Duties

Other diesel engines may run at medium speed or high speed, depending upon their duty. These engines serve various auxiliary and emergency roles on a vessel.

Some examples of applications for these engines include:

-

Lifeboat engines

-

Main / Emergency power generation

-

Emergency fire pump prime movers

-

Emergency air compressor

-

Cargo pump prime movers

-

Hydraulic power packs

6.9.6 Medium-Speed and High-Speed Engines for Electrical Power

Medium-speed and high-speed engines are often used as direct drives for the generation of electrical power.

-

The medium-speed four-stroke trunk piston engine can be found on large merchant vessels, even if the main engine is a two-stroke crosshead engine. In these cases, they supply the electrical power by driving alternators.

-

Medium-speed engines (300 - 1200 rpm) are common for smaller ship propulsion and power plants driving electrical generators.

-

High-speed engines (approximately 1,000 rpm and greater) are typically used for small electrical generators.

6.9.7 Medium-Speed Engines as Main Propulsion (with Reduction Gear)

Medium-speed engines (and occasionally high-speed engines) are used, through some form of speed reduction, as main propulsion engines.

Need for a Reduction Gear:

-

The optimum rotational speed of a medium-speed engine is 300 to 1500 RPM.

-

This speed is higher than the optimum propeller speed for high efficiency.

-

In order to improve the overall performance of the energy conversion system, reduction gears are fitted to enable both the engine and the propeller to work efficiently.

Gearing is used to transmit power in a drive line at a different rotational speed than the prime mover, which also changes the transmitted torque. A gearbox reduces the rotational speed, allowing the prime mover to run at its optimum design speed while the propeller operates at its optimum, lower speed.

6.9.8 Approximate Speed Range Comparison

comparision of different speed engines

Slow speed (up to 150rpm)

Medium speed (up to 1000rpm)

High speed (above 1000rpm)